Keeping an eye on how well your supply chain is doing is one of the best things you can do to make sure your business is successful. There are a lot of steps in the supply chain, such buying things, making things, moving them, and getting them to customers. It’s quite hard to find faults and make things function more smoothly without detailed information about how each aspect of this system is doing.

This complete lesson will show you the most important supply chain measures and KPIs (Key Performance Indicators) that businesses use to keep an eye on performance, make better choices, and keep the supply chain running smoothly. These KPIs and measurements help businesses run more smoothly, save money, make more products, and make customers happy.

What are the supply chain’s key performance indicators (KPIs) and metrics?

When you utilize supply chain metrics, you look at specific pieces of information to see how well different supply chain operations are doing and how to make them better. These metrics look at a number of various things, such how well you buy items, how much you can sell, how well you move things around, and how well you keep track of your stock. Businesses can find methods to improve, make their operations more effective, and make smart decisions based on up-to-date data by keeping an eye on these metrics.

Key Performance Indicators (KPIs) are a group of metrics that look at the most important bits of information that are directly related to a company’s strategic goals. These KPIs make it simple to see how well the supply chain is functioning and how quickly it is reaching its goals. KPIs show companies how successfully they are managing their stocks, meeting consumer needs, and keeping costs down.

Why Supply Chain KPIs Will Be Important in 2025

As businesses become global and rely more on technology, supply chain management is changing. This makes it even more important to have KPIs that you can trust. Key performance indicators (KPIs) for the supply chain will be more significant than ever in 2025. This is the reason:

1. Supply chains are getting bigger and more international.

When companies get more and more of their goods and resources from diverse parts of the world, it gets harder to keep track of these complicated supply chains. KPIs are a way to measure how well certain areas, suppliers, and vendors are doing. This helps firms maintain their supply chains functioning smoothly and cheaply all across the world.

2. Technology that works better

IoT, ERP systems, Warehouse Management Systems (WMS), and Transportation Management Systems (TMS) are all new technologies that help us gather and analyze data in real time. These tools enable firms keep track of and measure how well their supply chain is performing at every stage. KPIs let businesses use this information to make wise choices and run their businesses better.

3. Earning money and keeping costs low

Businesses need to make their processes more efficient because the costs of raw materials, transportation, and labor are going increasing. Key performance indicators (KPIs) like cost-per-unit and freight expenses assist businesses keep their costs down while still giving their clients the service they expect.

4. What Customers Want

Customers want companies to deliver swiftly and give them great service. Companies can use key performance indicators (KPIs) like on-time delivery, order cycle time, and perfect order rate to see how well they are meeting customer expectations and change their plans if they need to.

5. Following the regulations and being good for the environment

As people become more worried about the environment, businesses need to pay more and more attention to sustainability. Companies can utilize KPIs like the amount of CO2 emissions per shipment or the percentage of packaging that is recycled to see how their actions influence the environment and make sure they are obeying sustainability rules.

How supply chain frameworks put KPIs in order

If a company has a robust framework, it may determine the KPIs that are most important to them depending on their goals. The SCOR Model (Supply Chain Operations Reference) is one of the most prevalent ways to combine supply chain KPIs. The SCOR model divides the supply chain into five main parts:

- Plan : In this step, you need to guess how much demand there will be, figure out how to meet that demand, and make sure that there is enough supply to meet it.

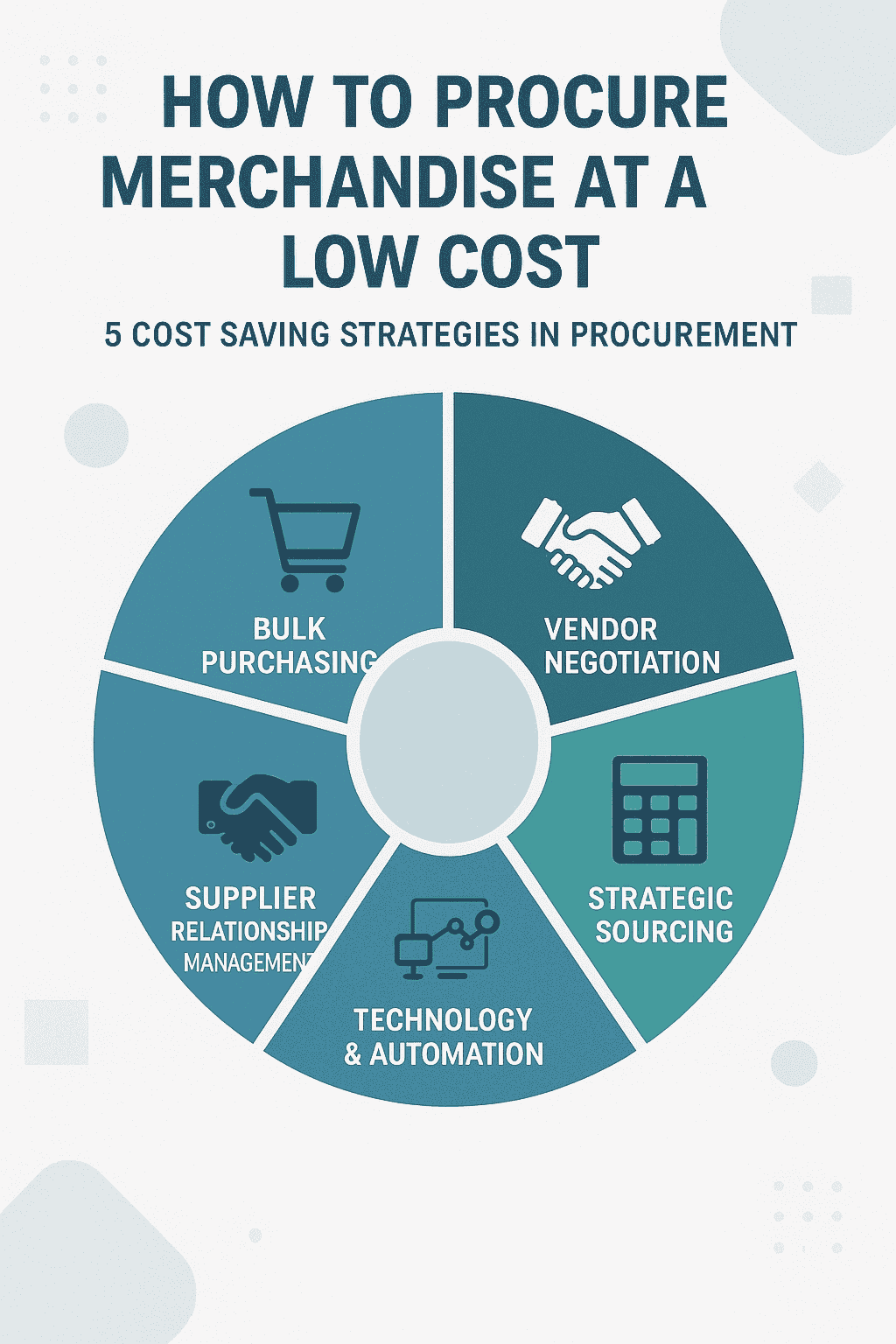

- Source : This procedure comprises choosing a vendor, buying goods, negotiating a contract, and making the deal.

- This contains ways to make things, check the quality, and plan when to make them.

- Deliver : This step is all about getting the goods to the customer. This includes shipping, transportation, and filling orders.

- Return : This step is all about dealing with returns, warranty claims, and repairs.

There are five techniques to measure success at each of these stages :

- Reliability : This looks at how often the supply chain keeps its commitments to clients, like how often orders are delivered on time and how correct they are.

- Responsiveness : This measures how quickly the supply chain reacts to changes, like when demand suddenly goes up or orders are changed.

- Agility : This assesses how well the supply chain can handle problems or changes that come up suddenly, including delays or not having enough products.

- Cost : This looks at how well the supply chain spends its money, such as how much it costs to ship something, how much it costs to retain inventory, and how much each item costs.

- Asset Management : This looks at how well the supply chain uses its resources, like how much inventory it has, how much space it has for storage, and how much it can produce.

The Most Important KPIs to Measure Supply Chain Success

1. On-Time Delivery (OTD) / On-Time In-Full (OTIF)

What It Looks At:

- On-time delivery (OTD) keeps track of how many orders are delivered on time.

- OTIF goes a step further by monitoring both the delivery time and whether the order is complete, which means that all the items are delivered without any missing.

Why It’s really important : One of the most important things you can do to keep clients happy is to be reliable. On-time delivery and OTIF are two important KPIs that show how successfully the supply chain is meeting consumer needs. When you miss deadlines, people get upset, and this could cost you business.

2. The number of orders that were perfect

What It Measures : The Perfect Order Rate tells you how many orders are delivered.

- On time

- In complete

- No harm done

- With the right forms

Why It’s Important : This key performance indicator (KPI) shows how happy customers are with your business as a whole. A high perfect order rate means that the supply chain does a great job at every step, from getting the order to delivering it.

3. The time it takes for a customer to make an order

This key performance indicator (KPI) shows how long it takes to fill an order, from when a consumer places it to when the item is delivered.

Why It’s Important : Shorter order cycle times can help with cash flow, customer service, and the expense of keeping inventory. Order cycle time is particularly significant in e-commerce and other fields where quick delivery is important to stay competitive.

4. The Mean Absolute Percentage Error (MAPE) shows you how close the prediction is to being true.

What It Measures : Forecast accuracy looks at how close the actual demand is to what the forecasting methods claimed it would be. The MAPE formula shows you how much the expected demand differs from the actual demand.

Why It’s important : To plan production and maintain track of inventories, you need to be able to accurately estimate demand. If your projections are wrong, you could end up with too much product, which costs money to keep, or not enough, which means you lose sales and make consumers mad.

5. How often do you sell your shares?

What It Measures : The merchandise turnover rate shows how many times products are sold and then replaced in a certain amount of time.

Why It’s Important : A high inventory turnover % means that a lot of people want the company’s products and that it is doing a good job of keeping track of its inventory. It shows that the business is moving goods swiftly through the supply chain and not keeping money tied up in stock that isn’t selling.

6. Days of Supply in Stock

What It Measures : This key performance indicator (KPI) shows how long the existing stock will last at the average pace of sales.

Days of supply shows how well a company is managing its inventory and helps it keep from having too much or too little stock. This is very important for keeping track of money coming in and going out and making sure that things don’t go to waste because they get old.

7. The cost of the supply chain as a percentage of sales

What It Measures : This key performance indicator (KPI) indicates the entire cost of running the supply chain as a percentage of total sales.

Why It’s Important : By keeping an eye on how much their supply chain costs in relation to their sales, businesses can determine how well they are using their resources. If the cost % goes up, it could mean that there are problems with making things, keeping track of inventory, or delivering things to where they need to go.

8. The Cash-to-Cash Cycle Time (C2C)

What It Measures : The cash-to-cash cycle shows how long it takes for a business to turn its revenues into cash.

Why It’s Important : Businesses may better manage their working capital when the cash-to-cash cycle is shorter. It means that a business can swiftly turn its assets into cash, which makes it more liquid and able to adjust its finances.

9. The time it takes to fill an order

This measure maintains track of how long it takes to get an order and subsequently deliver it to the consumer.

Why It’s Important : Customers are less happy when their orders take longer to fill. Customers expect orders to be filled more quickly. This is especially true in retail and e-commerce, where quick delivery is very important.

10. Suppliers Always Deliver on Time

What It Measures : This key performance indicator (KPI) shows how many orders suppliers deliver on time, as promised in the delivery plan.

Why It’s Important : For the supply chain to perform as it should, suppliers need to deliver on time. When suppliers don’t send products on time, it can throw off everything in the supply chain, from how much stock you have to how long it takes to make things.

Steps for Using Supply Chain KPIs

Step 1: Write down what you want to do.

Make sure that your KPIs are in accordance with your strategic goals before you choose them. You need to define key performance indicators (KPIs) for each goal, including saving money, providing better customer service, or being more environmentally responsible.

Step 2: Choose the Right KPIs

Pick KPIs that will directly affect how well your supply chain works. If you’re having trouble with delivery dependability, for instance, examine OTD and OTIF first.

Step 3: Set rules and goals

Make sure that each KPI has clear goals, such delivering 95% of the time. To find out how well your supply chain is doing, compare your results to those of other companies in your field.

Step 4: Set up automatic data collection

Collect data on their own using ERP, WMS, and TMS systems. This makes sure everything is correct, cuts down on the number of mistakes made by hand, and helps you see KPIs straight away.

Step 5: Use dashboards to look at your data

Make a dashboard for each job to help you keep track of your KPIs. These dashboards should provide information in real time and be easy for important personnel in different departments to get to.

Step 6: Look and change

Meet with important team members on a regular basis to go over KPIs. Change KPIs as corporate strategies, market conditions, or problems change.

Conclusion

The supply chain KPIs are more than just numbers on a dashboard; they are important tools that show you how well your supply chain is working and how healthy it is. Businesses may save money, speed up operations, and make customers happier by keeping an eye on indicators like order cycle time, on-time delivery, and inventory turnover.

By keeping an eye on the relevant KPIs, organizations may see where their supply chain isn’t functioning as well as it should. In the very competitive field of supply chain management, picking the proper KPIs is key to staying ahead of the competition and having long-term success.